- This topic has 1 voice and 0 replies.

Viewing 0 reply threads

Viewing 0 reply threads

- You must be logged in to reply to this topic.

› Forums › General › News (General) › The Real cost of downtime in manufacturing

Tagged: BizDev_G2, Industrial_V4

#News(General) [ via IoTForIndiaGroup ]

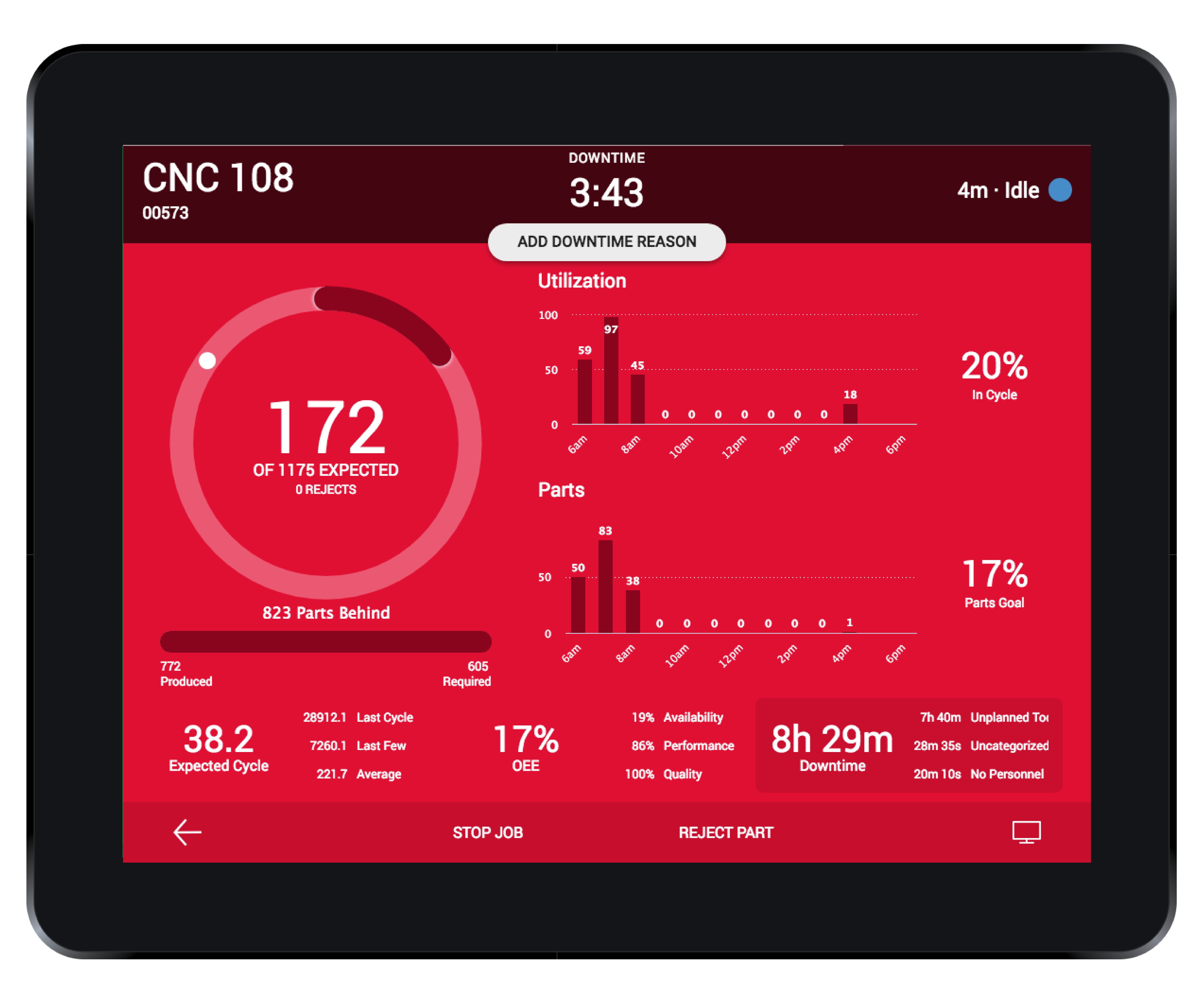

When unplanned downtime occurs, no value is being produced but the cost of overhead operations continues to grow, which directly impacts a company’s bottom line. According to Analyst firm Aberdeen Research, 82 percent of companies have experienced unplanned downtime over the past three years and that unplanned downtime can cost a company as much as $260,000 an hour!

A new study sponsored by ServiceMax (conducted by Vanson Bourne of GE Digital), “After The Fall: Cost, Causes and Consequences of Unplanned Downtime,” surveyed 450 field service and IT decision makers across the Globe and in many industries including, manufacturing, medical, oil and gas, energy and utilities, and transportation. The study found that productivity, IT, and customer service are still hit hardest by unplanned downtime, and that the reverberation is felt across businesses as a whole.